Select by CategoriesParametric Specifications

Resources

Frequently Asked Questions

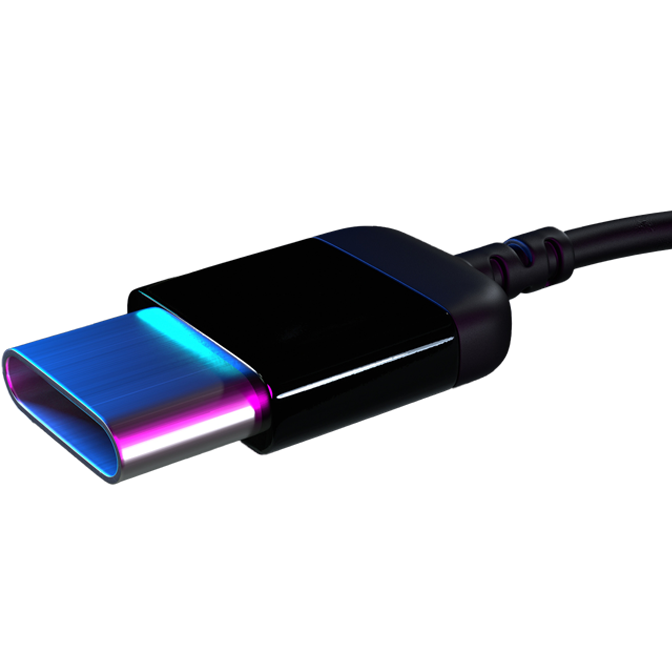

An ESD diode is a fast-acting protection device designed to clamp electrostatic discharges, preventing damage to sensitive electronics. It features low clamping voltage, low capacitance for high-speed signal integrity, minimal leakage current, and comes in compact packages for space-constrained designs.

- VRWM (Reverse Stand-Off Voltage)

- Clamping voltage (Vc)

- Peak pulse current ratings (e.g., 8/20 µs)

- Capacitance (critical for high-speed lines)

Match the diode's VRWM slightly above your normal line voltage, ensure clamp and capacitance specs align with your system, and consider packaging (e.g. low-profile, array options).

In general, choose unidirectional for DC power lines.

In general, choose bidirectional for data/communication lines or AC interfaces.